Thermal Scanning Overview

In this Page you will discover how by using sophisticated thermal scanning equipment, Micron Group Scan, Identify, and diagnose electrical problems within electrical switchboards and HVAC motor control systems for commercial and industrial buildings.

Why is Thermal Scanning so important? Electrical problems left unrepaired ultimately result in failure and far worse potential fire. Faults within electrical switchboards and mechanical systems can be complex, are not easily detectable, and most importantly not always apparent to the naked eye. Left undetected faults within these systems lead to failure with devastating losses for both equipment and in the systems they control. Revenue and time lost from electrical system failure can result in major setbacks. Micron Group use Thermal Scanning as a tool to diagnose potential faults before they develop into critical hazards affecting both equipment and human life.

Thermal Scanning

CATEGORY:

Heat Imaging

TYPE:

CASE STUDY:

Heat Mapping

Thermal Scanning Benefits

What are the benefits? Micron Group uses Thermal Scanning to provide a non-invasive way to check for electrical faults not visible to the naked eye.

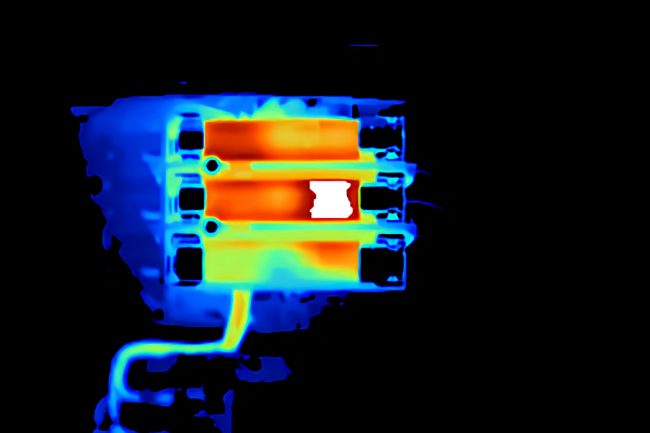

Thermographic imaging of building electrical switchboards and HVAC systems is a non-intrusive technology we use to check for non-visible faults and connection problems. Most importantly, Micron Group use thermography to get instant real-time results. It also spares our clients the downtime that often comes with other forms of inspections, and it even allows for our technicians to undertake immediate repairs. In other words the customer achieves simultaneous and uninterrupted testing and maintenance.

Thermal Scanning allows us to undertake electrical preventative maintenance ensuring confidence in your electrical infrastructure. Besides preventing loss, electrical thermography makes it possible to remain compliant and is considered a requirement by many insurance companies to attain and keep policies active.

Thermal Scanning provides the following benefits

• Non-Invasive

• No Downtime

• Quiet Service

• Minimize Risks such as fire and equipment failure

• Planned Outages for repairs to be undertaken

• Reduce Costs caused by a major fault

• Increase Compliance

• Increase Safety

Thermal Scanning Benefits

CATEGORY:

Thermographic Scan

TYPE:

Electrical Thermography

CASE STUDY:

Thermal Scanning

Our Specialized Thermal Scanning Cameras and Imaging Equipment

Micron Group use the latest Thermal Scanning cameras and equipment providing all our clients the most up to date precision scanning tools to ensure all potential electrical faults are effectively identified, logged, and repaired

Unobtrusive with No Power Interruption. Micron Group use the most up to date calibrated imaging cameras from renowned manufacturers such as Fluke, Flir and HT coupled with sophisticated software to ensure your equipment is scanned and analysed without compromise. Detailed Service Reports: Our clients receive the detailed categorised (picture in picture) reports after each Thermographic Scan outlining potential faults, the severity of the fault and repair action required to eliminate potential electrical hazards

Thermal Scanning Camera

CATEGORY:

Thermal Scanning

TYPE:

Electrical Thermography

CASE STUDY:

Heat Mapping

Specialists in Thermal Scanning Electrical Switchboards

Thermal Scanning of Electrical Switchboards using a thermal imaging camera is a tool Micron Group uses to detect problems and determine the health of an electrical switchboard without the need to interrupt power.

What’s the Importance of thermal scanning switchboards? Weather it be a large main switchboard feeding a high-rise commercial building, industrial plant or a small office, thermographic heat imaging is a powerful tool used to determine the health of the switchboard and internal components. When electricity is generated and used, it creates heat, if the connections within the switchboard it’s busbars or internal circuit breakers are loose (due to wear and tear or human error during construction) heat builds up. Over time the connection may fail resulting in disastrous outcomes. Excessive heat on a connection is referred to as a ‘Hot Joint’. Micron Group thermographic imaging services can assist to locate and repair ‘Hot Joints’ before a serious problem arises.

Thermal Scanning Electrical Switchboards

CATEGORY:

Thermal Scanning

TYPE:

Electrical Switchboards

CASE STUDY:

Switchboard Thermal Imaging

Specialist in Thermal Scanning Data Centres

Micron Group regularly provide Thermal Scanning services for critical environments such as data centres and communication rooms identifying and repairing electrical faults ensuring your critical systems remain online and always operate efficiently.

Data Centres consume a enormous amount of power, if the server load within these areas is high or if cooling is inadequate, electrical switchboards feeding the data centre will overheat, causing internal components such as busbars and circuit breakers to develop ‘Hot Spots’. Hot spots are weak points in the electrical connection, which if left unrepaired will ultimately lead to failure and downtime.

Micron Group’s specialized and highly trained technicians will scan switchboards and other critical electro-mechanical services within your critical data centre environment to ensure systems remain reliable, functional, and always online.

Specializing In Thermographic Imaging of Data Centres

CATEGORY:

Thermographic Analysis

TYPE:

Data Centres

CASE STUDY:

Thermal Scanning Electrical Motors

Thermal Scanning electric motors and motor connections is a technique Micron Group use to ensure your HVAC motor systems remain reliable and are operating correctly as originally intended.

Loose electric motor connections, poorly crimped copper lugs, and copper corrosion can cause excess heat, when left unrepaired these poor connections develop into ‘Hot Joints.’ Wear and tear in the form of worn bearings or misaligned shafts increase friction causing a dramatic drop in system efficiency. This ultimately affects motor performance in the way of slower fan or pump speeds, an increase in energy costs, and excess heat and noise which inevitably causes motor or plant failure. Micron Group use Thermographic Imaging as an essential tool to determine motor health by measuring and carefully analysing specific temperature thresholds, ultimately reducing the risk of failure or fire.

Thermographic imaging is a useful tool Micron Group use to determine

• Heat Mapping Identifies faults in electric motors Pumps and Fans

• Using our scanning techniques we identify Friction Points

• Worn Bearings and Misaligned Shaft identified by Heat Mapping

• Identifies faults with Belts, Conveyors, Motors, Pumps and Fans

• Our Heat Imaging techniques also Identify inefficiencies and faults in HVAC generators and standby systems.

Thermographic Imaging Electric Motors

CATEGORY:

Analysis for HVAC

TYPE:

Motor Imaging

CASE STUDY:

HVAC Thermal Scanning

Micron Group uses thermographic analysis as a non-invasive way to check for electrical HVAC faults which are not visible to the naked eye.

Most importantly, thermal imaging of HVAC systems provides a non-invasive way to check for non-visible electrical faults and get real-time results. It also avoids downtime that is often accompanied with other forms of inspection, and it even allows our technicians to undertake immediate repairs, offering our clients uninterrupted testing and maintenance simultaneously.

Why is Thermographic imaging so important? Left unrepaired electrical problems ultimately result in infrastructure failures. Most importantly, electrical mechanical HVAC systems are complex, and in most cases electrical problems are not easily detectable, ultimately leading to equipment failure with devastating results for the systems they control. For instance, motors controlling a data centre’s cooling system may fail due to a ‘Hot Joint’ (a stressed electrical connection which overheats and may melt), such failure can result in major setbacks and financial loss. Micron Group uses up to date calibrated thermal scanning cameras from renowned manufacturers such as Fluke or Flir coupled with sophisticated software to ensure your equipment is scanned and analyzed without compromise.

Electrical ThermographyAbove all, Micron Group’s electrical thermography offers the ability to inspect mechanical and electrical equipment such as HVAC mechanical switchboards, electrical connections, motors, variable speed drives, sensors, and automation equipment without powering them off. In fact, Micron Groups’ professional thermal scanning techniques means no downtime and equipment errors can be detected immediately.

Thermal Scanning of Machinery

CATEGORY:

HVAC

TYPE:

Mechanical Electrical

CASE STUDY: